+86-371-86151827

[email protected]

- +86-371-86151827

- High-tech Development Zone, Zhengzhou, China

- 08:30 am – 06:00 pm

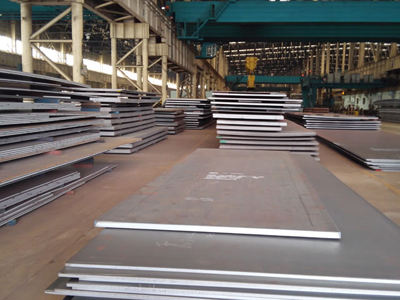

As we all know, due to the process characteristics of "three highs and one low", hot rolling technology will cause certain defects in rolled steel sheets. The main disadvantage is that the iron oxide scale produced during high temperature rolling (800 ℃ ~ 1000 ℃) will cause the poor surface quality of A ST52 steel.

Moreover, if the hot-rolled A ST52 steel is too thin, the temperature distribution and temperature drop on the hot-rolled sheet will be uneven, which will lead to uneven distribution of the hot-rolled A ST52 steel after cooling, and the properties will be greatly affected. The rolling thickness of hot rolled A ST52 steel is limited.

Therefore, in actual production, the thickness of hot-rolled A ST52 steel is generally not less than 1.5 mm, which limits the scope of practical application of hot-rolled A ST52 steel.

Compared with the high-temperature hot rolling technology, cold rolling is a room temperature rolling technology, and the rolling temperature is lower, so cold rolling A ST52 steel fundamentally completely avoids the existence of iron oxide scale and temperature caused by the hot rolling process. Uneven organization. Therefore, compared with hot-rolled steel sheet, cold-rolled A ST52 steel has outstanding advantages.

Hot ProductsMore+

If you have any need about our steel products, Please send email to [email protected] or leave a message to use this function. we will reply you ASAP!